Magnetic Belt Conveyor: A Key Solution for Efficient Materials Transport

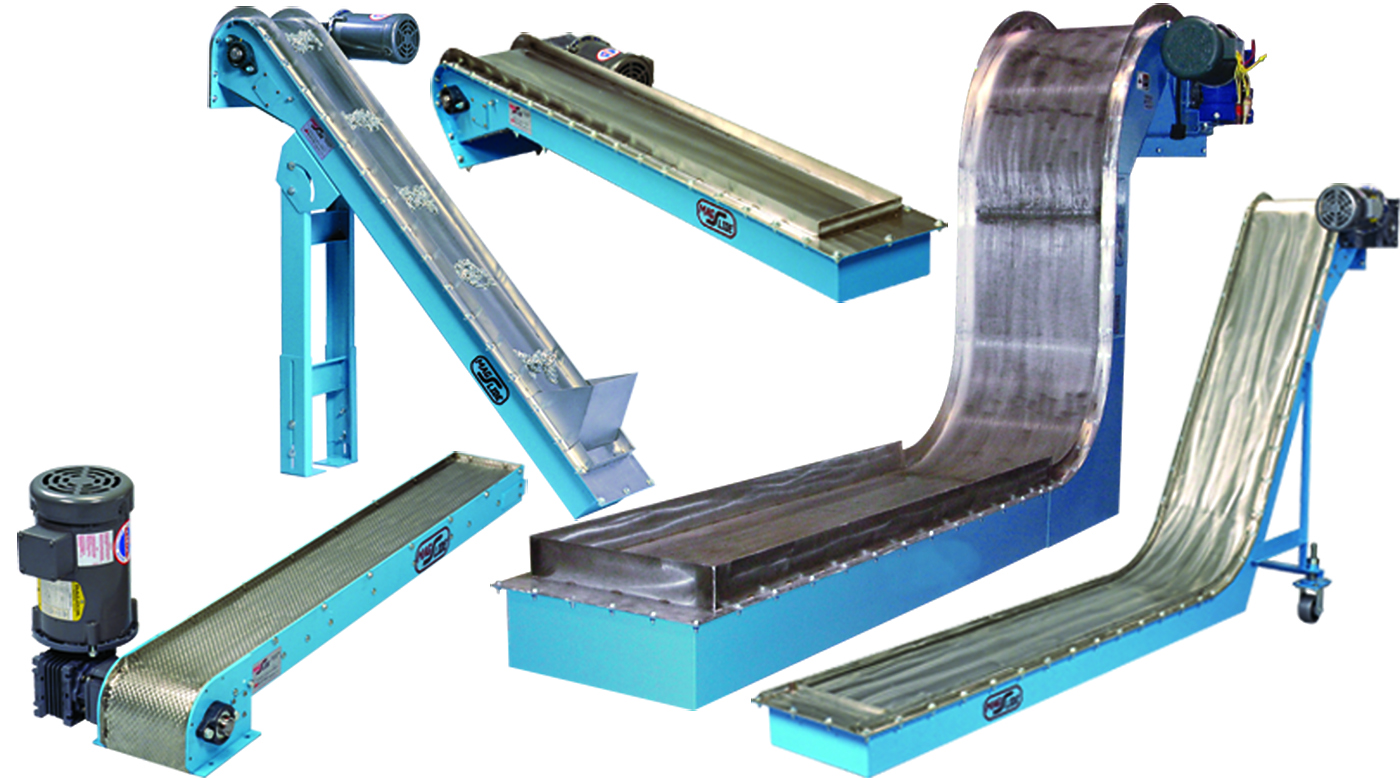

In modern production, recycling, as well as handling markets, effective component managing is actually essential to ensuring productivity as well as safety. The magnetic belt conveyor has become a groundbreaking service for relocating ferrous products rapidly and also tightly with commercial procedures. Unlike conventional district conveyors, magnetic belt bearers use the energy of magnetics to hold metallic materials securely in position as they the conveyor belt. This magnetic pressure allows the efficient transit of metals like steel, iron, and also aluminum without the risk of slipping or falling. Magnetic Belt Conveyor have actually transformed component handling through delivering a trustworthy approach for firmly carrying iron products, making them important in a large variety of sectors.  Among one of the most substantial benefits of magnetic district conveyors is their ability to deal with iron components that are usually difficult to take care of using conventional belt devices. In sectors like recycling, scrap metal processing, and manufacturing, metal objects require to become delivered safely and securely without the threat of dropping or acquiring dislodged. The magnetic belt conveyor accomplishes this by embedding magnets either in the conveyor belt itself or underneath it, which generate a magnetic field strength tough good enough to keep metal things. This component is actually particularly important in reprocessing plants where steel fragment should be separated coming from other materials and transferred to assigned handling areas. By using the magnetic pressure to secure components in place, magnetic belt bearers get rid of the requirement for hand-operated handling, making the whole process much more effective and risk-free. Another significant benefit of Magnetic Belt Conveyor is their adaptability. These conveyors may be created to work in various alignments and also arrangements, relying on the specific needs of the operation. Whether products require to be moved horizontally, up and down, or even at an incline, magnetic conveyors can be actually customized to satisfy the assembly-line production's style. Moreover, various sorts of magnets could be made use of to produce electromagnetic fields along with differing durabilities, producing it possible to transfer components of numerous sizes and also weights. Using electromagnets, for instance, permits for the stamina of the magnetic field strength to become adjusted as needed, offering adaptability when handling different ferrous components. This adaptability makes Magnetic Belt Conveyor suited for a wide variety of requests, from small-scale manufacturing to huge reprocessing functions. The effectiveness of magnetbandförderer is actually one more factor that specifies all of them apart from typical conveyors. Using magnetics permits for a continual circulation of products, reducing the likelihood of disturbances in manufacturing. Unlike various other bearers that may require constant changes or routine maintenance to deal with different products, magnetic bearers offer a even more secure and reliable methods of transporting iron products. The smoothness of the operation suggests that there is actually a lot less damage on the unit, which reduces the demand for fixings and also expands the lifestyle of the tools. In high-speed production environments, this constant, trusted action of materials is essential for maintaining productivity and also decreasing down time. The performance of magnetic belt bearers assists make sure that functions rush perfectly which components are moved rapidly as well as securely with the creation procedure.

Among one of the most substantial benefits of magnetic district conveyors is their ability to deal with iron components that are usually difficult to take care of using conventional belt devices. In sectors like recycling, scrap metal processing, and manufacturing, metal objects require to become delivered safely and securely without the threat of dropping or acquiring dislodged. The magnetic belt conveyor accomplishes this by embedding magnets either in the conveyor belt itself or underneath it, which generate a magnetic field strength tough good enough to keep metal things. This component is actually particularly important in reprocessing plants where steel fragment should be separated coming from other materials and transferred to assigned handling areas. By using the magnetic pressure to secure components in place, magnetic belt bearers get rid of the requirement for hand-operated handling, making the whole process much more effective and risk-free. Another significant benefit of Magnetic Belt Conveyor is their adaptability. These conveyors may be created to work in various alignments and also arrangements, relying on the specific needs of the operation. Whether products require to be moved horizontally, up and down, or even at an incline, magnetic conveyors can be actually customized to satisfy the assembly-line production's style. Moreover, various sorts of magnets could be made use of to produce electromagnetic fields along with differing durabilities, producing it possible to transfer components of numerous sizes and also weights. Using electromagnets, for instance, permits for the stamina of the magnetic field strength to become adjusted as needed, offering adaptability when handling different ferrous components. This adaptability makes Magnetic Belt Conveyor suited for a wide variety of requests, from small-scale manufacturing to huge reprocessing functions. The effectiveness of magnetbandförderer is actually one more factor that specifies all of them apart from typical conveyors. Using magnetics permits for a continual circulation of products, reducing the likelihood of disturbances in manufacturing. Unlike various other bearers that may require constant changes or routine maintenance to deal with different products, magnetic bearers offer a even more secure and reliable methods of transporting iron products. The smoothness of the operation suggests that there is actually a lot less damage on the unit, which reduces the demand for fixings and also expands the lifestyle of the tools. In high-speed production environments, this constant, trusted action of materials is essential for maintaining productivity and also decreasing down time. The performance of magnetic belt bearers assists make sure that functions rush perfectly which components are moved rapidly as well as securely with the creation procedure.  Routine maintenance is actually another location where magnetic belt conveyors attract attention compared to standard bearer units. The decline in friction as a result of the magnetic tourist attraction implies that the waistbands experience a lot less wear and tear over opportunity, extending their life expectancy as well as decreasing the frequency of repair work. Additionally, Magnetic Belt Conveyor are relatively simple to sustain, as their parts are actually developed for easy gain access to as well as cleaning. For sectors such as food processing, where care specifications are actually a concern, magnetic conveyors may be promptly disassembled and cleansed to make sure observance with health and wellness laws. The absence of relocating parts including gears and also rollers in a lot of magnetic conveyor layouts likewise supports their low-maintenance nature, making all of them an best option for locations wanting to minimize down time and also repair service costs. In add-on to their productivity and also reduced servicing, Magnetic Belt Conveyor offer safety and security benefits that are actually crucial in many commercial environments. When taking care of hefty or hazardous products, like pointy steel components or scrap metal, employees are at risk of personal injury coming from managing these components manually. By automating the transport of iron components, magnetic conveyors reduce the necessity for employees to literally take care of hazardous items, decreasing the risk of reduces, strains, and also mishaps. Moreover, the magnetic field strength holds products safely and securely in location, lessening the danger of things decreasing the bearer and leading to damages to the assembly-line production or even presenting a protection risk. In settings like reusing centers or even fragment backyards, where metal objects could be large, sharp, as well as complicated to relocate, magnetic bearers enhance laborer safety and security by maintaining components included and also ensuring that they relocate properly with the device.

Routine maintenance is actually another location where magnetic belt conveyors attract attention compared to standard bearer units. The decline in friction as a result of the magnetic tourist attraction implies that the waistbands experience a lot less wear and tear over opportunity, extending their life expectancy as well as decreasing the frequency of repair work. Additionally, Magnetic Belt Conveyor are relatively simple to sustain, as their parts are actually developed for easy gain access to as well as cleaning. For sectors such as food processing, where care specifications are actually a concern, magnetic conveyors may be promptly disassembled and cleansed to make sure observance with health and wellness laws. The absence of relocating parts including gears and also rollers in a lot of magnetic conveyor layouts likewise supports their low-maintenance nature, making all of them an best option for locations wanting to minimize down time and also repair service costs. In add-on to their productivity and also reduced servicing, Magnetic Belt Conveyor offer safety and security benefits that are actually crucial in many commercial environments. When taking care of hefty or hazardous products, like pointy steel components or scrap metal, employees are at risk of personal injury coming from managing these components manually. By automating the transport of iron components, magnetic conveyors reduce the necessity for employees to literally take care of hazardous items, decreasing the risk of reduces, strains, and also mishaps. Moreover, the magnetic field strength holds products safely and securely in location, lessening the danger of things decreasing the bearer and leading to damages to the assembly-line production or even presenting a protection risk. In settings like reusing centers or even fragment backyards, where metal objects could be large, sharp, as well as complicated to relocate, magnetic bearers enhance laborer safety and security by maintaining components included and also ensuring that they relocate properly with the device.